Home / OSHA Restaurant Safety

Restaurant kitchens are high-hazard environments governed by strict federal mandates. We analyze workplace injury cases against OSHA standards (29 CFR 1910) to determine if the establishment failed its ‘General Duty’ to provide a safe workspace. We assess if the injury resulted from a specific code violation or systemic safety neglect.

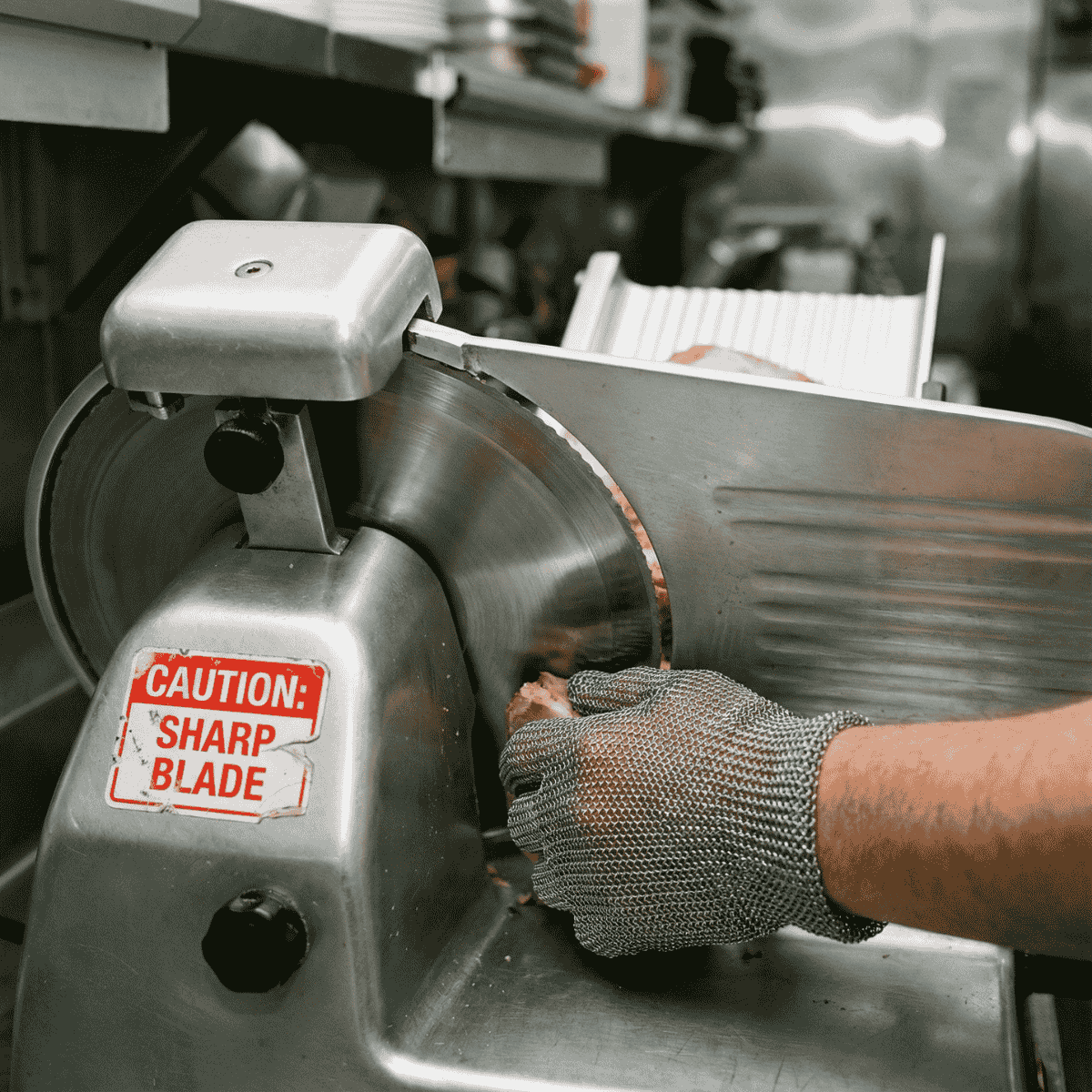

Common kitchen injuries—from slicer amputations to deep fryer burns—often stem from missing Personal Protective Equipment (PPE) or disabled safety guards. We audit the equipment maintenance logs and ‘Lockout/Tagout’ procedures to identify if the restaurant prioritized speed over safety protocols.

We also evaluate Hazard Communication (HazCom) compliance. Was the staff properly trained on the chemicals they used? We review Safety Data Sheets (SDS) availability and chemical handling training records to establish liability in chemical burn or respiratory injury cases.

We identify the specific regulatory breaches that contributed to the injury, focusing our analysis on these four critical OSHA standards often violated in kitchens.

Amputations often occur when safety guards are removed for speed. We inspect slicers and mixers to determine if interlocks were bypassed or guards were missing, a direct violation of federal guarding mandates.

Did the employer provide and enforce the use of cut-resistant gloves and burn sleeves? We assess if the injury resulted from a failure to conduct the required “PPE Hazard Assessment” for the station.

Chemical burns imply a failure to train. We verify if Safety Data Sheets (SDS) were actually accessible to staff and if the injured worker was trained on the specific corrosive risks they handled.

Cleaning energized equipment is a leading cause of severe injury. We audit if the venue had specific written LOTO procedures to fully de-energize machinery before maintenance or deep cleaning began.

A signed safety acknowledgment form is often where the defense ends, but our analysis begins. We distinguish between a ‘paper program’ and a functioning safety culture. We investigate if safety gear was actually available, if ‘training’ was just a quick signature during a busy shift (dry-labbing), and if management tacitly encouraged bypassing safety guards to speed up service.

Verifying if cut gloves were actually available on the line.

Detecting faked signatures or "rush-job" safety briefings.

Identifying if guards were routinely removed for cleaning.

Proving if chemical safety data was actually available to staff.

Analyzing historical injury trends the venue ignored.

Secure these critical items to evaluate OSHA compliance and equipment safety.

Request the past 3-5 years of OSHA 300 Logs. We analyze these to identify patterns of similar injuries, proving the employer had “constructive notice” of the hazard but failed to act.

Obtain the original operator’s manual for the specific machine (slicer/mixer) involved. We compare the manufacturer’s safety warnings against the actual training provided to the employee.

Secure the Safety Data Sheets (SDS) for any chemical involved in a burn injury, along with the specific “Hazard Communication” training log signed by the injured employee.

Request maintenance work orders and “Lockout/Tagout” (LOTO) procedure logs. This reveals if the machine was known to be defective or if safety guards were removed for maintenance and never replaced.

Our involvement extends beyond the expert report. We partner with legal teams to decipher complex operational evidence, providing the technical clarity needed for summary judgment motions, settlement negotiations, and courtroom advocacy.

Common questions about restaurant expert witness services

We review slip and fall incidents, service-related injuries, food safety issues, crowd management failures, staff negligence claims, and operational liability matters in restaurant environments.

We review slip and fall incidents, service-related injuries, food safety issues, crowd management failures, staff negligence claims, and operational liability matters in restaurant environments.

We review slip and fall incidents, service-related injuries, food safety issues, crowd management failures, staff negligence claims, and operational liability matters in restaurant environments.

We review slip and fall incidents, service-related injuries, food safety issues, crowd management failures, staff negligence claims, and operational liability matters in restaurant environments.